How Does the Film Extruder Work?

In the realm of medical equipment, the film extruder plays a crucial role in manufacturing various plastic films used in a wide range of medical applications.

This article aims to provide an overview of the film extruder, its working principle, cost considerations, and its applications in the medical field.

This article aims to provide an overview of the film extruder, its working principle, cost considerations, and its applications in the medical field.

What is a Film Extruder?

A film extruder is a specialized machine used to produce continuous plastic films of different thicknesses and widths. It is a key component in the process of extrusion, which involves melting raw plastic materials and shaping them into a film form.

The resulting film can have diverse properties such as flexibility, transparency, and barrier properties, making it suitable for various applications.

The resulting film can have diverse properties such as flexibility, transparency, and barrier properties, making it suitable for various applications.

How Does the Film Extruder Work?

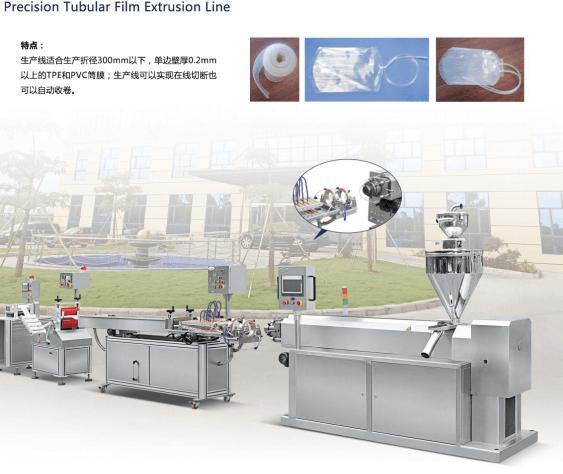

The film extruder consists of a feeding system, an extrusion screw, a die, cooling systems, and a winding system. The process begins with the raw plastic material being fed into the extruder. Inside the machine, the plastic is heated and melted by the extrusion screw.

The molten plastic is then forced through a specialized die, which shapes it into a continuous film of the desired thickness and width. After exiting the die, the film is rapidly cooled to solidify it, and it is then wound onto a roll for further processing or packaging.

The molten plastic is then forced through a specialized die, which shapes it into a continuous film of the desired thickness and width. After exiting the die, the film is rapidly cooled to solidify it, and it is then wound onto a roll for further processing or packaging.

Is Extrusion an Expensive Process?

The cost of the extrusion process can vary depending on several factors such as the type of plastic material used, the desired film properties, production volume, and the complexity of the extruder.

While the initial investment in a film extruder and associated equipment can be substantial, the economies of scale come into play with larger production volumes. Additionally, advancements in technology have led to more efficient and cost-effective extrusion processes over time.

While the initial investment in a film extruder and associated equipment can be substantial, the economies of scale come into play with larger production volumes. Additionally, advancements in technology have led to more efficient and cost-effective extrusion processes over time.

What are the Applications of the Film Extruder?

The film extruder finds extensive applications in the medical field, where plastic films are utilized for various purposes. Some notable applications include:

●Medical Packaging

Plastic films produced by the extruder are commonly used for sterile packaging of medical devices, instruments, and pharmaceutical products. These films provide a protective barrier against contaminants, ensure product integrity, and allow for easy sterilization processes.

●Wound Dressings and Surgical Drapes

Thin, flexible plastic films produced by the extruder are employed in wound dressings and surgical drapes. These films offer superior breathability, moisture management, and barrier properties, helping to create a sterile environment and promote optimal wound healing.

●Medical Imaging

Plastic films can be used in medical imaging applications such as X-ray and MRI. They act as a protective layer for imaging plates and films, ensuring image clarity while minimizing patient exposure to radiation.

●Catheter Tubing

Extruded plastic films are also used in the production of catheter tubing, providing flexibility, biocompatibility, and low friction properties. These films enable the smooth insertion and movement of catheters within the body, facilitating critical medical procedures.

What is Plastic Film Used for?

Plastic films produced by the film extruder have numerous uses beyond the medical field. They are widely employed in packaging applications, including food packaging, consumer goods packaging, and industrial packaging.

Plastic films are also utilized in agriculture for greenhouse covers, mulching films, and crop protection. Additionally, they find applications in the construction industry, electrical insulation, and various consumer products.

Plastic films are also utilized in agriculture for greenhouse covers, mulching films, and crop protection. Additionally, they find applications in the construction industry, electrical insulation, and various consumer products.

Conclusion

The film extruder is an essential tool in the medical equipment industry, enabling the production of versatile plastic films used in a wide array of medical applications.

Its ability to shape raw plastic materials into continuous films with specific properties makes it indispensable in the manufacturing process. As technology continues to advance, the film extruder will likely play an increasingly important role in meeting the growing demand for innovative medical solutions.

Its ability to shape raw plastic materials into continuous films with specific properties makes it indispensable in the manufacturing process. As technology continues to advance, the film extruder will likely play an increasingly important role in meeting the growing demand for innovative medical solutions.