The Basics of Extruders and Compounding Machines

Extruders and compounding machines play a vital role in the medical equipment industry, enabling the production of a wide range of essential devices and components. In this article, we will explore the basics of extruders and compounding machines, their functions, types, applications, and the importance of quality control in the medical equipment manufacturing process.

What are Extruders?

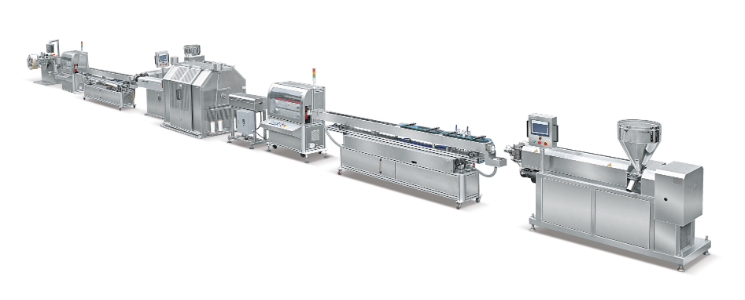

Extruders are machines used to shape and process various materials into a continuous profile with a specific cross-sectional shape. In the medical equipment industry, extruders are crucial for producing components like tubes, catheters, and device coatings. Two common types of extruders used in medical equipment manufacturing are single-screw extruders and twin-screw extruders.

Single-screw extruders are the simplest and most common type. They consist of a heated barrel, a rotating screw, heater bands, and a die. The screw rotates within the barrel, pushing the material forward, melting it, and forcing it through the die to create the desired shape. On the other hand, twin-screw extruders offer enhanced mixing capabilities and are often used for more complex medical device manufacturing processes.

Single-screw extruders are the simplest and most common type. They consist of a heated barrel, a rotating screw, heater bands, and a die. The screw rotates within the barrel, pushing the material forward, melting it, and forcing it through the die to create the desired shape. On the other hand, twin-screw extruders offer enhanced mixing capabilities and are often used for more complex medical device manufacturing processes.

Understanding Compounding Machines

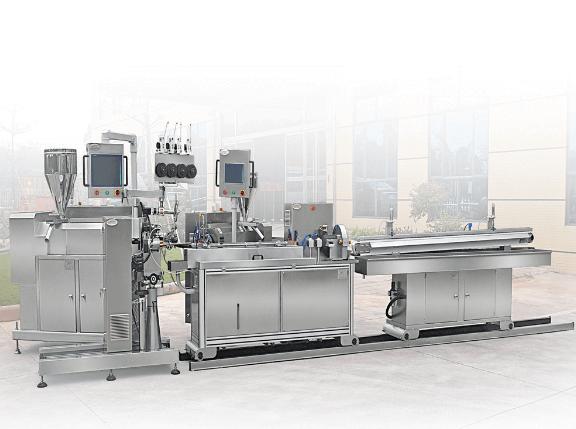

Compounding machines are employed to blend multiple materials, additives, or colorants to create customized polymer formulations. In the medical equipment industry, compounding machines are essential for producing materials with specific properties and characteristics required for various medical devices. Two common types of compounding machines used are batch compounding machines and continuous compounding machines.

Batch compounding machines mix a predetermined quantity of materials in a closed chamber to achieve the desired formulation. Continuous compounding machines, as the name suggests, provide a continuous process where materials are fed into a mixing chamber, blended, and then pelletized for further processing.

Batch compounding machines mix a predetermined quantity of materials in a closed chamber to achieve the desired formulation. Continuous compounding machines, as the name suggests, provide a continuous process where materials are fed into a mixing chamber, blended, and then pelletized for further processing.

Applications of Extruders and Compounding Machines in the Medical Equipment Industry

Extruders and compounding machines find wide-ranging applications in the medical equipment industry, enabling the production of critical devices and components.

Extrusion-based processes are used in tube and catheter production, where medical-grade polymers are extruded into precise shapes and dimensions. Extruders also play a significant role in applying coatings to medical devices, ensuring biocompatibility, lubricity, and drug elution properties. Furthermore, filament extrusion using extruders is employed in the growing field of 3D printing for manufacturing patient-specific implants and surgical guides.

Compounding machines are utilized to create custom material formulations for medical devices, tailoring the properties of polymers to meet specific requirements such as flexibility, strength, or biocompatibility. They are also instrumental in producing color and additive masterbatches, allowing precise control over coloration and the incorporation of additives like antimicrobial agents or radiopaque materials. Moreover, compounding machines enable the blending of different polymers for producing specialized components in medical equipment manufacturing.

Quality Control and Regulatory Considerations

Quality control is of utmost importance in the medical equipment industry to ensure product safety, reliability, and compliance with regulatory standards. Extrusion and compounding processes must meet stringent requirements to produce materials and components with consistent quality.

Compliance with industry standards such as ISO 13485 (Quality Management Systems for Medical Devices) and FDA regulations is crucial. Manufacturers must adhere to documented procedures, conduct rigorous testing, and maintain traceability of materials throughout the production process.

Key quality control measures include monitoring and controlling parameters like temperature, pressure, and screw speed during extrusion and compounding processes. Additionally, material characterization, testing for mechanical properties, and biocompatibility assessments are vital to guarantee the safety and performance of medical equipment.

Conclusion

As the medical equipment industry continues to evolve and innovate, it is essential for professionals to stay updated with advanced techniques and advancements in extrusion and compounding technologies. Continued research and development in these areas will contribute to the production of high-quality medical devices that improve patient care and advance healthcare practices.

By grasping the fundamentals of extruders and compounding machines, manufacturers and professionals can harness their capabilities to meet the growing demands of the medical equipment industry, ultimately enhancing patient outcomes and driving innovation in healthcare.

By grasping the fundamentals of extruders and compounding machines, manufacturers and professionals can harness their capabilities to meet the growing demands of the medical equipment industry, ultimately enhancing patient outcomes and driving innovation in healthcare.