| Price | Negotiable |

| MOQ | 1 Set |

| Delivery Time | 40 days |

| Brand | ZK |

| Place of Origin | China |

| Certification | CE ISO Certification |

| Model Number | PPC32-3, PPC64-8 |

| Packaging Details | Export standard container or as customers' requirements |

| Payment Terms | L/C, D/A, D/P, T/T |

| Supply Ability | 25 Set / Sets per Month |

| After sale service | Engineers available to service machinery overseas | Filtration area | 865-4450(㎡) |

| Installation | under supervision of our engineer | Place of Origin | China |

| Motor type | AC Motor | Packaging Details | Export standard container or as customers' requirements |

| Product Name | Baghouse Dust Collection Equipment | Model Number | PPC32-3, PPC64-8 |

| Supply Ability | 25 Set / Sets per Month | Certification | CE ISO Certification |

| Brand Name | ZK | Payment Terms | L/C, D/A, D/P, T/T |

| Price | Negotiable | Delivery Time | 40 days |

| Minimum Order Quantity | 1 Set | Voltage | 220V/380V/440V |

| Model | PPC Series Pulse Jet Bag Filter | Solution | Customized |

Baghouse Dedusting Filter Bag Dust Collector For Iron Concentrate

Pulse

Jet

Bag

Filter

Introduction:

PPC

Series

Pulse

Jet

Bag

Filter

incorporates

the

advantages

of

other

bag

filters

as

compartmental

blow-back,

pulse

jet

cleaning.

It

is

suitable

to

the

treatment

of

high

concentration

dust,

simplifying

the

technical

process

of

dust

treatment

and

reducing

investment

of

device.

| System composition | |

| 1 | Upper box is includes cover plate and air outlet. |

| 2 | Middle box is includes perforated plate, filter frame, sock and venture. |

| 3 | Under box is includes ash hopper, air intake and access door Jetting system contains control valve, pulse electromagnetic value, injection pipe and air pocket. |

Baghouse

Dedusting

Filter

Working

Principle:

During

the

dust

gas

goes

into

middle

box

and

under

box,

the

dust

can

be

attached

to

filter

bag

and

outgoing

gas

after

going

through

venture

and

upper

box.

With

the

increasing

of

dust,

press

loss

for

dust

bag

is

increased,

which

will

fed

back

to

controller.

Receiving

and

issuing

commands,

the

controller

will

touch

off

every

pulse

valve

to

make

gas

erupts

from

each

jetting

hole,

then

pass

a

venture

tube

and

spray

into

corresponding

filter

bag.

The

filter

bag

expands

rapidly

under

instantaneous

reaction

of

airflow,

dust

fallen

off

of

the

filter

bag,

so

the

filter

bag

can

be

recycled.

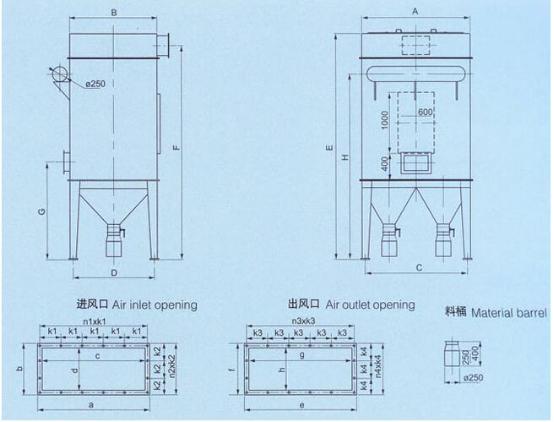

Dust Collector Structural Drawing:

| Model | PPC128-6 | PPC128-9 | PPC128-10 | PPC128-2×6 | PPC128-2×7 | PPC128-2×8 | |

| Volume(m³/h) | 67300 | 100900 | 112100 | 134600 | 157000 | 179400 | |

| Air speed(m/min) | 1.2-2.0(Speed varies at different dust points) | ||||||

| Filtration area(㎡) | 935 | 1402 | 1558 | 1869 | 2181 | 2492 | |

| Net filtration area(㎡) | 779 | 1246 | 1402 | 1713 | 2025 | 2336 | |

| No. of bag(pc) | 768 | 1152 | 1280 | 1536 | 1792 | 2084 | |

| Resistance(Pa) | 1470-1770 | ||||||

| Minus pressure(Pa) | 7000 | ||||||

| Dust content at inlet(g/m³) | <1300 | ||||||

| Dust emission(g/m³) | ≤0.1 | ||||||

| Compressed air | Pressure(Pa) | (5-7)×105 | |||||

| Air consumption | 3.6 | 5.4 | 6 | 7 | 8.3 | 9.5 | |

| (m³/min) | |||||||

| Pulse valve | Qty(pc) | 12 | 18 | 20 | 24 | 28 | 32 |

| Size | 2-1/2″ | ||||||

| Elevation valve | Qty(pc) | 6 | 9 | 10 | 12 | 14 | 16 |

| Size(mm) | Valve Φ725,air tank Φ100 | ||||||

| Discharge device YJD-26 | Outlet 300×300mm Capacity 24m³/h | Double flap valve 305×915 | |||||

| Screw conveyor | Model | Dia. Φ300,capacity 21m³/h | N/A | ||||

| Gearbox | XWD2.2-5-1/43,power 2.2Kw | N/A | |||||

| Air slide | Air slide 250mm,flow rate 2.0m³/㎡, Pressure 6860pa,If the dust content exceeds 700g/m³ at inlet, bag filter with big screw conveyor should be considered. | ||||||

| Bag size and material | Dia.×lengthΦ130×3050,Gross weight of polyethylene felt 450g/㎡,temperature 120℃ | ||||||

| Insulation area(㎡) | 125 | 196 | 205 | 223 | 247 | 262 | |

| Total weight(approx.)(Kg) | 24120 | 31680 | 34680 | 43920 | 52680 | 60000 | |

| Note 1: Net filtration area means the area of one chamber during dust removing. | |||||||

| 2: The compressed air consumption is based on supply of compressed air pipe from an air compression station. The consumption should be considered to be 1.3 times more if the supply is provided by an independent air compressor. | |||||||