Phidix

Pull-Only

T-Flex

Control

Cable:

Built

to

Withstand,

Engineered

to

Flex

For

industrial

systems

that

demand

reliable

linear

actuation

under

tension-only

loads,

the

Phidix

Pull-Only

T-Flex

Cable

offers

a

performance-optimized

solution—combining

high

tensile

strength,

low

deflection,

and

a

durable

multi-layer

conduit

design.

This

series

is

purpose-built

to

operate

in

environments

where

space

is

limited,

loads

are

repetitive,

and

uptime

is

non-negotiable.

Trusted

in

clutch

systems,

throttle

actuation,

brake

lockouts,

and

engine

stop

mechanisms—T-Flex

is

engineered

to

perform

where

conventional

cables

can't

keep

up.

What

Makes

T-Flex

Different

|

Feature

|

Standard

Pull-Only

Cable

|

Phidix

T-Flex

Series

|

|

Conduit

Design

|

Single-layer

steel

wrap

|

Dual-layer

compressed

flat

wire

wrap

|

|

Protective

Sheath

|

PVC

only

|

PP,

PVC,

or

bare

options

available

|

|

Inner

Liner

|

None

or

standard

plastic

|

Optional

high-density

PP

liner

for

low

friction

|

|

Application

Fit

|

General

braking

or

locking

|

High-cycle

motion

control

with

routing

complexity

|

|

Customization

|

Basic

end

fittings

|

Threaded

rod,

clevis,

ball/socket,

dashboard

mounts

|

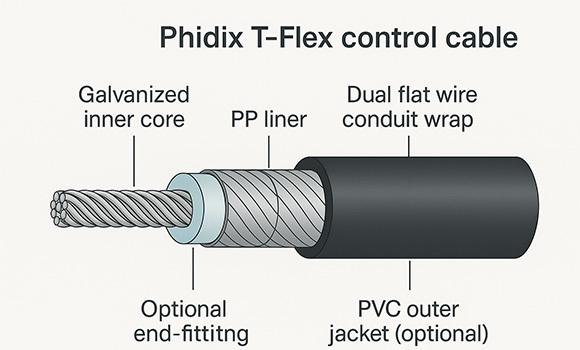

Internal

Structure

&

Motion

Control

Integrity

•

Innermember:

High-strength

galvanized

or

tinned

steel

multi-strand

cable,

available

in

0.078"

to

0.188"

diameters.

•

Conduit

Construction:

Multiple

steel

wire

configurations

with

optional

high-density

inner

liners.

•

Outer

Sheath:

Choice

of

PVC

or

polypropylene

jacket;

or

no

outer

sheath

for

chassis-integrated

protection.

•

Motion

Characteristics:

Low

deflection,

excellent

bend

performance,

low

friction

pull

stroke.

This

cable

assembly

is

not

designed

for

compression—pull

only.

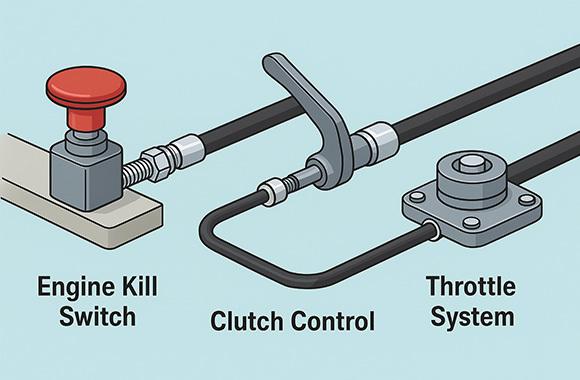

Typical

Applications

•

Clutch

Cables

–

Heavy-duty

truck

or

marine

disengagement

systems

•

Engine

Kill

Switch

Lines

–

Manual

fuel

or

ignition

shutoff

•

Throttle

Pull

Lines

–

Mechanical

regulation

on

gensets

and

mobile

hydraulics

•

Lockout

&

Disconnect

Mechanisms

–

Emergency

stop

interlocks

or

latch

systems

•

Industrial

Equipment

Routing

–

Linear

cable

systems

with

complex

routing

geometry

Build

Options

&

Component

Flexibility

Inner

Core

•

Steel

strand:

1x7,

1x19,

or

armored

core

•

Coated

or

bare,

depending

on

environmental

need

Liner

•

High-density

PP

for

reduced

pull

resistance

Outer

Jacket

•

Black

PVC

(default)

•

Polypropylene

(PP)

for

higher

temperature

tolerance

•

No

jacket

for

conduit-in-conduit

routing

End

Fittings

•

Clevis

rod

end

(UNF

or

metric)

•

Swivel

terminals

•

Knob

actuators

•

Threaded

sleeves

or

ball-stops

•

Dash

panel

mounts

Full

custom

assemblies

available

to

match

your

panel

layout,

control

handle,

or

actuation

lever.

Technical

Data

Snapshot

|

Parameter

|

Value

Range

|

|

Max

Load

|

Up

to

2200

lb

(varies

by

core

and

fitting)

|

|

Travel

Range

|

1.5"–6"

(custom

travel

on

request)

|

|

Min.

Bend

Radius

|

5"

typical

|

|

Temp

Tolerance

|

-40°C

to

+105°C

(varies

by

jacket

type)

|

|

Core

Diameter

Options

|

0.078"

/

0.125"

/

0.188"

|

FAQs

Q:

Can

the

T-Flex

cable

be

used

in

push-pull

systems?

A:

No,

this

series

is

strictly

pull-only

by

design.

Q:

What

if

I

need

higher

temp

resistance

or

chemical

tolerance?

A:

Use

the

PP-jacket

version

or

contact

us

for

jacketless

configurations.

Q:

Can

I

get

a

version

with

dashboard

knob

actuator?

A:

Yes.

Threaded

or

snap-fit

knob

interfaces

are

available

upon

request.

Q:

How

do

I

specify

length

and

end

fittings?

A:

Refer

to

our

A

(total

length)

and

L

(travel

length)

sizing

sheet.

Our

team

can

assist.