| Price | Negotiable |

| MOQ | 100KGS |

| Delivery Time | 30 - 60 Work Days |

| Brand | YUHONG |

| Place of Origin | China |

| Certification | EN ISO 13485:2016 |

| Model Number | SUS304, SUS316L |

| Packaging Details | Plywood Cases |

| Payment Terms | T/T, L/C |

| Supply Ability | According to Clients' Requirement |

| Place of Origin | China | Applications | Precision Instruments, Medical Devices, Electronic Equipments, Aerospace, etc. |

| Packaging Details | Plywood Cases | Model Number | SUS304, SUS316L |

| Supply Ability | According to Clients' Requirement | Certification | EN ISO 13485:2016 |

| Gauge | 10G - 34G | Brand Name | YUHONG |

| Payment Terms | T/T, L/C | Materil Grades | SUS304, SUS316L |

| Type | Welded Tubes | Price | Negotiable |

| Delivery Time | 30 - 60 Work Days | Minimum Order Quantity | 100KGS |

| Wall Thickness | RW, TW, ETW, UTW | Technique | Cold Drawn |

SUS304 316L Stainless Steel Hypodermic Needle Tube For Medical Injection ISO9626

Stainless steel needle tubes are generally manufactured by SS304, 304Ni8.5, 304Ni9, SS316L materials,which have good corrosion resistance. If the drawn needle tube size is smaller and thinner, the Ni content of stainless steel must be higher. YUHONG GROUP is professional for various kinds of stainless steel needle tubes from 10 Gauge to 34 Gauge, such as sterile hypodermic needles, insulin needles, dental needles and so on. As for wall thickness, there are four types of SUS304/316L stainless steel needles, including RW, TW, ETW, UTW for customers' selection. We can also supply straight/coil type stainless steel capillary tubes with 1.5 or 2 meters per piece generally. If you're interested in stainless steel needles and capillary tubes, our group's needle tubes will be a good choice for you.

Manufacturing

Process

Of

Stainless

Steel

Needles:

Stainless

steel

needle

tubes

are

welded

and

cold

drawn

tubes.

They

are

welded

from

polished

stainless

steel

strips(general

size:12.7mm

x

0.2mm),

using

the

newest

TIG

multi-electrode

welding

technique,

and

then

processed

by

cold

drawing,

annealing

and

ultrasonic

cleaning

to

special

sizes

with

smooth

surface

finish.

The

needle

end

is

bevelled,

forming

a

sharp

tip

in

order

to

inject

into

the

skin

easier.

Features Of Stainless Steel Needles:

1.

Durable

Use

2.

Good

Corrosion

Resistance

3.

Excellent

Tolerance

4.

Smooth

Surfce

Finish

5.

High

Precision

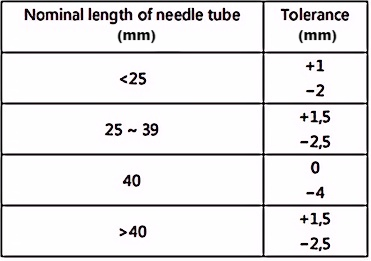

Length Tolerance Of Needle Tubes:

Applications Of Needle Tubes:

1.

Sterile

Hypodermice

Needle

2.

Injection

Needle

3.

Dental

Devices

4.

Infusion

Needle

5.

Veterinary

Tubular

Devices

6.

Medical

Devices

7.

Precision

Instruments

8.

Surgical

Instruments

9.

Electronic

Equipments

10.

Ophthalmology

11.

Aerospace

12.

Food

&

Beverage

Industries

13.

Clothing

Making